CNC Plasma Cutting Services: A Breakthrough for Custom Steel Fabrication Projects

27 September 2024

CNC plasma cutting services revolutionise custom steel fabrication projects. Learn about its adaptability in delivering results for various industries.

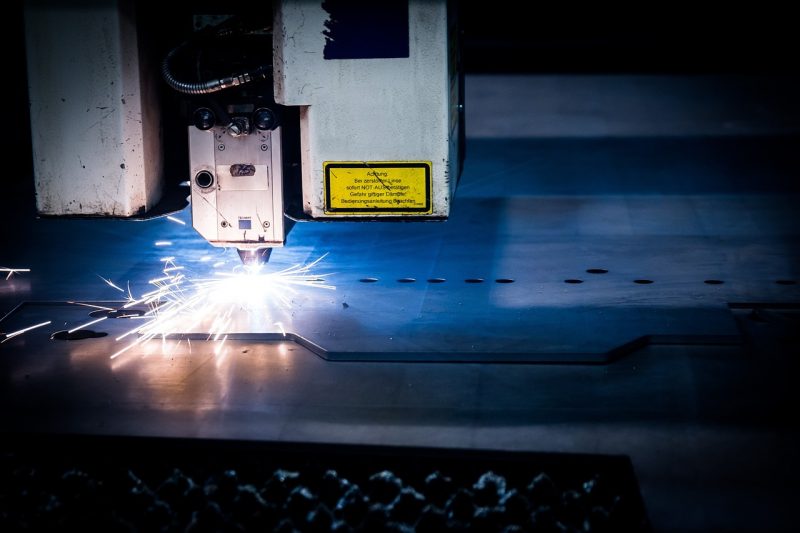

CNC plasma cutting services have revolutionised the field of custom steel fabrication, offering unparalleled precision and efficiency. This advanced technology allows for the creation of intricate designs with minimal waste, making it ideal for a wide range of industries. By integrating CNC plasma cutting into fabrication processes, businesses can achieve faster production times and higher quality results, setting a new standard in the industry.

What is CNC Plasma Cutting?

CNC plasma cutting is a process that uses a high-velocity jet of ionised gas (plasma) to cut through electrically conductive materials such as steel, aluminium, brass, and copper. This method is controlled by a computer numerical control (CNC) system, which ensures unmatched accuracy and repeatability in producing complex shapes and patterns.

The CNC system guides the plasma torch along a predetermined path, following a digital design blueprint. This enables fabricators to create intricate cuts with precision, whether for small batches or large-scale production runs.

The Advantages of CNC Plasma Cutting Services

CNC plasma cutting services offer a multitude of benefits that make them an ideal choice for custom steel fabrication projects. These advantages include:

• Precision and Accuracy: The CNC system ensures that every cut is made with pinpoint accuracy, adhering closely to the design specifications. This is especially crucial for projects requiring intricate details and tight tolerances.

• Speed and Efficiency: CNC plasma cutting is significantly faster than traditional cutting methods. The high-speed plasma jet can cut through thick materials in a fraction of the time, enabling quicker project completion.

• Versatility: This technology is not limited to just one type of material. CNC plasma cutting can handle a wide range of metals, including steel, stainless steel, aluminium, and copper. This versatility makes it suitable for various industries, from automotive to construction.

• Consistency and Repeatability: Once the CNC system is programmed, it can produce identical parts repeatedly, ensuring consistency across all units. This is particularly beneficial for mass production runs.

• Minimal Material Distortion: The high-speed plasma jet causes less heat distortion compared to other cutting methods, preserving the integrity of the material and reducing the need for secondary processing.

Applications of CNC Plasma Cutting in Custom Steel Fabrication

The versatility and precision of CNC plasma cutting services have made them indispensable across various industries. Some of the key applications include:

• Architectural Fabrication: From decorative metalwork to structural components, CNC plasma cutting enables the creation of complex and aesthetically pleasing designs that meet both functional and artistic requirements.

• Automotive Manufacturing: CNC plasma cutting is used to produce precision parts for vehicles, including chassis components, brackets, and exhaust systems.

• Industrial Equipment: Custom steel fabrication for machinery and industrial equipment often requires precise and durable parts, which CNC plasma cutting can efficiently produce.

• Marine and Aerospace: In industries where material strength and accuracy are critical, CNC plasma cutting provides the precision needed for fabricating components that meet stringent safety and performance standards.

CNC plasma cutting has revolutionised the field of custom steel fabrication, offering unparalleled precision, versatility, speed, and efficiency. WS Fabrication’s expertise in this technology enables us to deliver exceptional results for a wide range of projects. If you’re seeking a reliable partner for your custom steel fabrication needs, look no further than WS Fabrication. Contact us for more information.

Optimized by: Netwizard SEO