Flat Springs Manufacturing from Design to Applications in Various Industries

23 January 2024

Get to know flat springs manufacturing by WS Fabrication, from design to diverse applications. Drive efficiency across industries. Call us at (03) 9729 0955.

Machines and devices used by different industries are often comprised of components that make them operational. One of the components they utilise is flat springs. Flat springs are mechanical devices that store and release energy when subjected to deflection or deformation, making them useful in industries that require predictable force and motion. They often feature a flat, slender, and flexible shape.

Flat Springs: The Manufacturing Process

Not all flat springs, however, feature the same characteristics. They can boast designs that are tailored to the needs of various industries. Some steps in manufacturing flat springs are as follows.

• Design and Prototyping: The manufacturing of flat springs begins with meticulous design and prototyping. Engineers carefully consider the intended application, load requirements, and environmental factors to create a design that meets performance expectations. Prototyping allows for testing and refinement before mass production.

• Material Preparation and Cutting: Once the design is finalised, the selected material undergoes preparation, including cutting into the desired dimensions. Precision in this phase is essential to ensure uniformity and consistency in the performance of the flat springs.

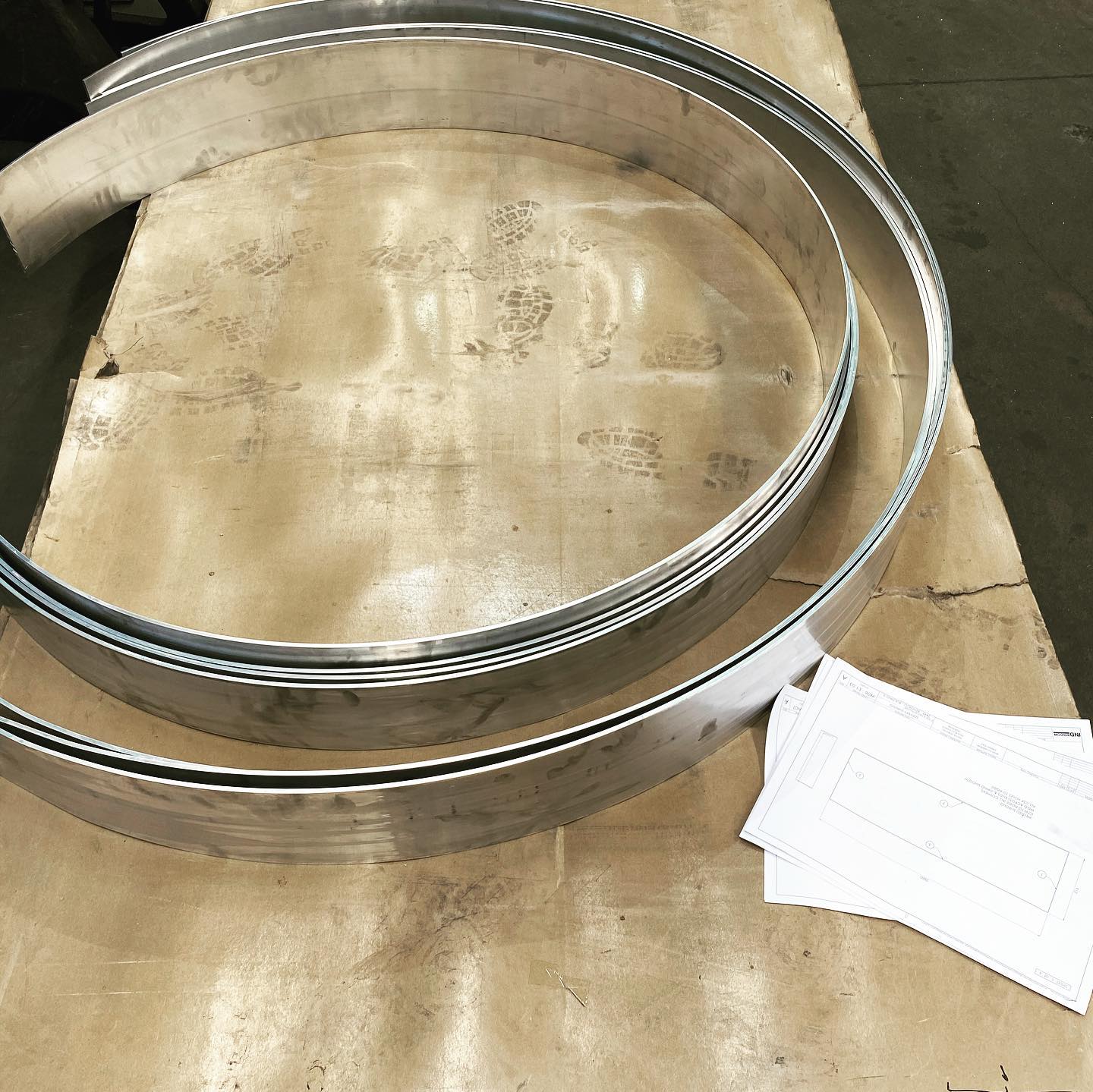

• Forming and Heat Treatment: Forming is an important step where the flat springs take shape. Depending on the type of spring and material used, various forming methods, such as stamping or coiling, are carried out. The process of heat treatment follows to enhance the properties of the material, providing the necessary strength and resilience.

• Finishing Touches and Quality Control: The manufacturing process concludes with finishing touches like deburring and surface treatment to ensure a smooth and corrosion-resistant surface. Rigorous quality control measures are done throughout the process to guarantee that each flat spring meets the specified standards and performs reliably in its intended application.

Guaranteeing Flat Springs’ Effectiveness

To guarantee the effectiveness of flat springs, various things must be considered.

Some notable things to consider in designing and manufacturing flat springs are load requirements, environmental conditions, and space constraints. Considering these things helps produce flat springs that can ensure optimal performance in specific applications. The materials used for the flat springs must likewise be considered. They must be able to resist corrosive substances, humidity, and temperature so that the flat springs can last longer.

Ultimately, you must partner with the right fabrication company. Working with us at WS Fabrication can be beneficial for you since we understand the intricacies of design, materials, and precision manufacturing. These things help us produce flat springs that meet or exceed your expectations.

Using Flat Springs Across Key Industries

When designed and fabricated optimally, flat springs can easily be effective in various industries.

First, they can be utilised in the automotive industry, particularly in suspension systems. Using them can contribute to a smooth and controlled ride in vehicles. Flat springs can also be used in electrical contacts in switches and retractable cords, making electronics and appliances durable. The medical industry can likewise use flat springs for implantable devices and diagnostic equipment. Even industrial machines can be integrated with flat springs, particularly on valves, clutches, and braking systems.

Flat springs embody the intersection of precision engineering and versatile functionality. When you invest in them from WS Fabrication, these springs can easily drive efficiency, enhance performance, and contribute to the reliability of your countless devices and machinery.

Optimized by: Netwizard SEO